concrete engraving

Using custom, air-powered cutting tools, a gas air compressor, and heavy-duty plastic templates, text, images, and designs, such as patterned borders, room motif accents, emblems, and company logos, can be precisely, efficiently engraved into horizontal concrete slabs - indoors and outside. Decorative concrete engraving becomes a permanent, distinct part of a concrete surface, similar to design work seen on tombstones and stone, residential sub-division vertical entry sign markers. At only an approximate depth of 1/16", decorative concrete engraving does not present a trip or safety hazard. Individual elements of engraved images and designs may be colored through use of acid-stains, solvent dyes, and acrylic water-based stains. Images and designs may be chosen from a preset catalog online, or converted from electronic files.

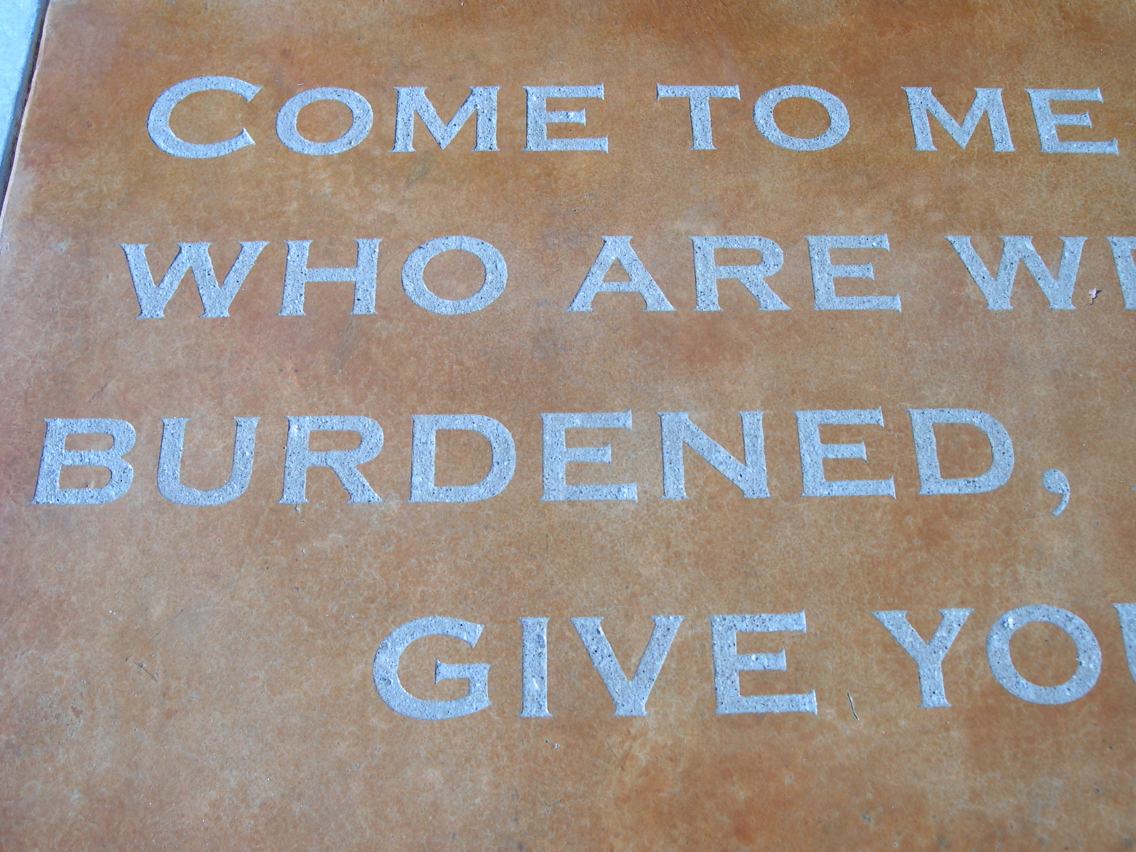

First set of photos shown below depicts concrete engraving project outside main entrance of church in Sterling Heights, Michigan. Pastor of church selected Bible verse that he wanted engraved into a specially-poured section of concrete, pre-colored with acid stain. He chose font type, size, and mitre; and one of our suppliers (Engrave-A-Crete) converted the verse into a template.

Second set of photos below reflects reproduction of a design on family heirloom jewelry case onto main floor of the heirloom owner's Irish pub restaurant in Farmington, Michigan, through decorative concrete engraving. You can read more about decorative concrete engraving process, and see online catalog of available templates at Engrave-A-Crete company web site.

A chronological view of the concrete engraving process: 1) the jewelry case; 2) the starting artwork; 3) the transfer of the image to floor; 4) the concrete engraving & staining of that image; and 5) the final image after applying the protective clear sealer.

One of the best things about concrete engraving is that the process produces little to no concrete dust. The cement particles that are chipped away during cutting are sufficiently large and heavy that they do not become airborne and present a respiratory hazard. The particles can simply be vacuumed up with a standard shop vac fitted with HEPA bag and cartridge filters.

There are other concrete engraving systems on the market that are not powered by an air compressor, including from Engrave-A-Crete, but these systems are either less precise and effective, such as automated or robotic engraving machines, or they are so elaborate and cost prohibitive that only a contractor who does concrete engraving full time would own one. These systems rely on sandblasting or shot-blasting. The equipment and system we use from Engrave-A-Crete is just as versatile, capable, precise and efficient.